Produksi Propilena dari Propana dan Oksigen

Meilana Dharma Putra

Program Studi Teknik Kimia

Fakulatas Teknik

Universitas Lambung Mangkurat

Propilena adalah salah satu hidrokarbon (kelompok olefin) yang sangat penting. Senyawa ini digunakan sebagai bahan dasar produksi beragam material seperti plastik, serat, film, tekstil, farmasi, dll. Proses produksi propilena dari propana dan oksigen adalah sangat menjajikan dan juga sebagai proses alternatif dari proses steam cracking ataupun katalisis dehidrogenasi. Hal ini dikarenakan, keberadaan oksigen sebagai reaktan bermanfaat dalam menurunkan penggunaan energi didalam proses dan menghindari proses regenerasi katalis. Namun secara umum, untuk memperoleh yield dan selektivitas yang tinggi dari propilena melalui proses tersebut adalah masih cukup sulit dikarenakan keberadaan okisgen menyebabkan rekasi oksidasi dari produk menjadi senyawa yang lain.

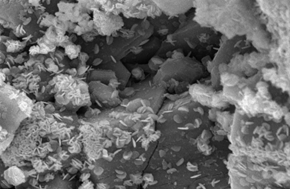

Kita telah mempelajari masalah tersebut, dimana keberadaan Sr pada V-Mo katalis meningkatkan performa dari katalis yaitu peningkatan konversi dari propane dan selektivitasnya, dan juga menurunkan reducibility dari katalis serta memperbaiki stabilitasnya (Putra dkk, 2011). Pada studi yang lain (Putra dkk, 2012a), penggunaan katalis tersebut juga mendukung hasil yang bagus terhadap performanya, dimana selektivitas tidak menurun pada saat meningkatkan temperatur dan waktu tinggal (space time) dari reaksi, sedangkan konversi meningkat. Pada studi kinetik (Putra dkk, 2012b), kita juga menyingkap bahwa keberadaan Sr (strontium) pada katalis V-Mo menghambat reaksi lebih lanjut (salah satu akar masalah dari proses tersebut). Di paper yang sama, peneliti menjawab kontroversi diantara para ilmuwan berkenaan dengan mekanisme reaksi dipermukaan katalis. Dimana, terbukti bahwa katalis pada umumnya semisal V-Mo yang mengalami reducibility yang cukup tinggi adalah sesuai dengan mekanisme Van-Mars Krevelen, sedangkan yang mengalami kurangnya tingkat reducibility seperti Sr-V-Mo cocok dengan mekanisme Langmuir-Hinshelwood. Banyaknya strontium ditanamkan pada katalis V-Mo juga dioptimasi pada studi yang lain (Putra dkk, 2013), katalis tersebut juga dievaluasi berdasarkan beragam hasil karakterisasi.

Oxidative Dehydrogenation of Propane to Propylene

Propylene is one of the most important light olefins used in the production of plastics, fibers, lubricants, films, textiles, pharmaceuticals, etc. Catalytic oxidative dehydrogenation (ODH) of propane to propylene stands as a promising alternative to steam cracking and catalytic dehydrogenation, because the presence of oxygen lowers energy requirements and eliminates the need for catalyst regeneration. However, in general, obtaining high yield with high olefins’ selectivity is still difficult due to tendency towards further oxidation. We has studied this issue, in which the presence of strontium in V-Mo catalyst enhanced the performance of the catalyst, i.e., increased conversion and selectivity, decreased reducibility of the catalyst and improved its stability (Putra et al., 2011). In another contribution, performance of the improved catalyst has been investigated further, i.e., in the presence of Sr, the selectivity did not decrease with increasing temperature and space time while the conversion increased (2012a). In a kinetic study (2012b), we revealed that the presence of strontium inhibited the consecutive reaction (i.e., oxidation of products). In addition, the same paper addressed the controversy amongst scientists regarding the reaction mechanism at the surface of the catalyst. It was proven that common catalysts such as V-Mo catalyst which has higher reducibility fits well the Mars-Van Krevelen mechanism, while lower reducibility catalysts, such as Sr-V-Mo catalyst, follow Langmuir-Hinshelwood mechanism. The strontium loading to V-Mo catalyst was also optimized, it was supported by various characterization results Putra et al, 2013).

Referensi:

- M.D. Putra, S.M. Al-Zahrani and A.E. Abasaeed, Catalysis Communications, 14 (2011) 107-110, Oxidative Dehydrogenation of Propane to Propylene over Al2O3-Supported Sr-V-Mo Catalysts

- M.D. Putra, S.M. Al-Zahrani and A.E. Abasaeed, Journal of Industrial and Engineering Chemistry, 18 (2012a) 1153-1156, Oxidehydrogenation of Propane to Propylene over Sr-V-Mo Catalysts: Effects of Reaction Temperature and Space Time

- M.D. Putra, S.M. Al-Zahrani and A.E. Abasaeed, Catalysis Communications, 26 (2012b) 98-112, Kinetic Study of Oxidehydrogenation of Propane over Al2O3-Supported Sr-V-Mo Catalysts

- M.D. Putra, M.K. Al-Mesfer, A.E. Abasaeed and S.M. Al-Zahrani, Journal of Chemical Engineering of Japan, 46 (2013), 389-395, Oxydehydrogenation of Propane over Supported Nickel-Molybdenum-Oxide Based Catalysts

- M.D. Putra, S.M. Al-Zahrani and A.E. Abasaeed, Journal of Energy Chemistry, 22 (2013), 778-782, Effect of Sr loading on Oxidehydrogenation of Propane to Propylene over Al2O3-Supported V-Mo Catalysts